Direct to Film: The Decoration For Hard-to-Decorate Things.

Prints That Keep Up With Your Design.

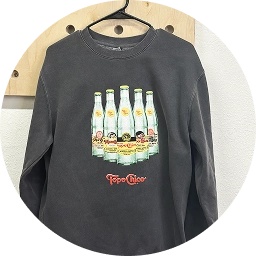

Direct to Film is a great fit for short runs, promotional projects, and specialty fabrics. This process transfers your design from film to fabric with heat and pressure, giving you long lasting prints on hard to decorate items.

Performance wear

TOtes

Hats

Specialty Items

What You Can Expect.

We use professional-grade films and inks that hold up wash after wash without peeling or losing color. DTF works on cotton, polyester, blends, and performance fabrics, making it a professional option for performance wear, hats, bags, and more. Every project starts with a test print to make sure the final result looks and feels right.

THE PRODUCTS TO PRINT

Questions About Direct to Film Printing.

How is Direct to Film different from screen printing?

Our DTF transfers are a hybrid process. They start as a digital print that can achieve a vibrant, full color spectrum – and even neons! Then an adhesive backing is screen printed on top of the digital print to ensure the best possible finish and adhesion to the garment after it is pressed.

What kind of garments can you print on?

The beauty of DTF is that works on most materials. Cotton, Polyester, Stretchy Spandex, and a variety other unique fabric blends are great for DTF transfers. It’s uniquely suited to decorate a lot of materials and fabrics that screen printing isn’t.

Does it feel different from screen printing?

Slightly, and we don’t recommend it for everything. But every technique has it’s place and DTF transfers are great for applications where the the feel of the print isn’t the focus.

What’s the turnaround time?

Most DTF projects are ready within three weeks once your proof is approved. We’ll confirm timelines before production starts so there are no surprises.